Chemical pumps play a vital part in many industries. They allow for the safe and effective transfer mixing, dispensing and mixing of chemicals. They are specifically constructed to handle corrosive, or abrasive fluids that cannot be taken care of by standard pumps. Chemical pumps can be divided into two categories namely centrifugal pumps as well as positive displacement pumps.

Working with reputable manufacturers of chemical pumps guarantees that you get access to high quality pumps that are up to industry’s strict standards. They use their experience in the development of durable, reliable and effective chemical pump designs. They make use of advanced technology in materials, manufacturing, and methods to withstand the corrosive and abrasive nature that chemical products bring. By partnering with trusted companies, you can ensure that businesses have access to pumps that can stand up to the toughest conditions and deliver optimal performance.

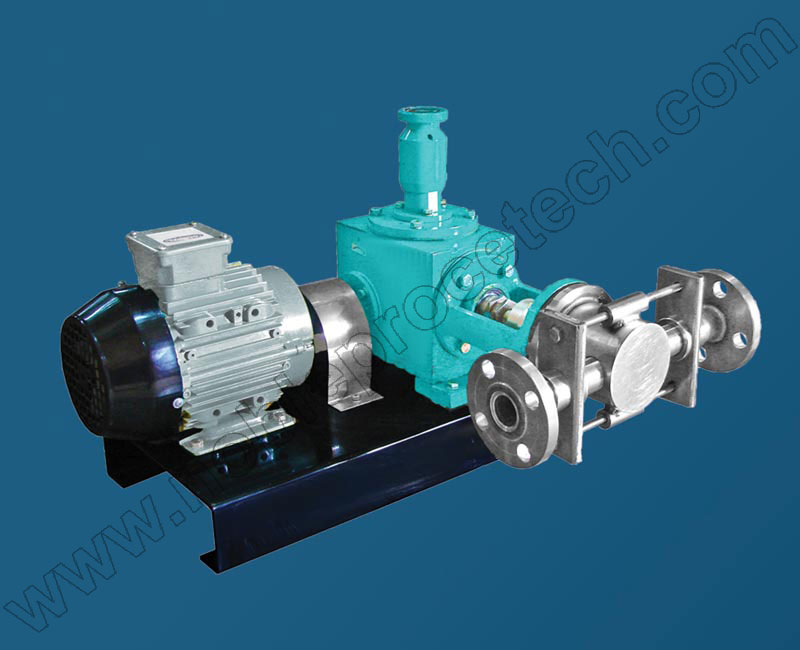

Chemical transfer pumps manufactured by manufacturers focus on designing pumps specifically for fluid-transfer applications. They can handle diverse chemicals, including acidic and sulphuric such as sodium hypochlorite and. Manufacturers of chemical transfer pumps concentrate on efficient management of fluids. They include elements like corrosion-resistant materials, leak-proof seals and precise flow control mechanisms such as. Their pumps are made to ensure safe, precise, and efficient chemical transfer.

Chemical pump suppliers are vital in helping companies find the right pumps to meet their needs. They offer a broad variety of chemical pumps from reputable manufacturers. They provide comprehensive product catalogs, technical assistance and customer support to assist businesses in selecting the correct pumps for specific needs. Chemical pumps offer an array of options for businesses to ensure they can select the ideal pump for their needs.

The importance of chemical pumps that are reliable goes far beyond the protection of the fluids. They are essential in keeping their integrity throughout the process of industrialization. If a pump is not functioning properly or is unreliable, it could cause costly leaks, inefficient processes and a risk of danger. In industries where chemicals are involved like the chemical production or petrochemical industries the consequences of a pump failure are often severe. For more information, click chemical pump suppliers

When purchasing chemical pumps that are durable companies can reduce the risks related to fluid management. The pumps have been created to resist the corrosive nature that is present in various chemical substances. This ensures that they remain in operation efficiently and effectively over the course of time. These pumps are made of sturdy materials, modern seal mechanisms and exact flow control. These attributes contribute to a safe and reliable flow of fluid.

Most chemicals pumps that are reliable include maintenance and support. These suppliers and manufacturers recognize the significance of chemical pumps and provide technical assistance, spare part availability, and maintenance inspections. This proactive approach enables the detection and resolution of any possible issues before they become serious. This helps ensure continued pump efficiency and helps reduce any unplanned downtime.

Chemical pumps are utilized in many industries, such as food processing, chemical manufacturing and petrochemicals. They are crucial for mixing, transfer of fluids and dispensing within these industries. Chemical pumps can also be utilized in high-temperature systems to provide heating and in refineries. Their capacity and flexibility to manage challenging fluids make them vital tools in ensuring effective and reliable industrial processes.

Think about factors like fluid type, flow requirements and operating conditions when selecting a chemical pumps. Trustworthy suppliers and chemical pump manufacturers can provide advice and support when it comes to selecting the ideal pump for the job. It is essential to prioritize safety as well as efficiency and reliability when making a selection to reduce the risk of accidents or accidents, maximize productivity, and minimize downtime.

The applications of chemical pumps in refineries extend far beyond the confines of the plant itself. These pumps can play a crucial role in off-site operations and contribute to the safe and efficient transfer of chemicals in a variety of contexts. Chemical pumps play an important part in the smooth running of refineries outside their boundaries. They are able to transport corrosive liquids, load and unload tanker truck as well as support maintenance and repairs. The durability, reliability and unique features of these pumps make them indispensable devices for off-site operations, where the handling of corrosive or abrasive chemicals requires accuracy, efficiency, and safety. The refineries can have the most reliable and seamless chemical transfer by investing in high quality chemical pumps, as well as using reliable producers and suppliers.